2023-04-14

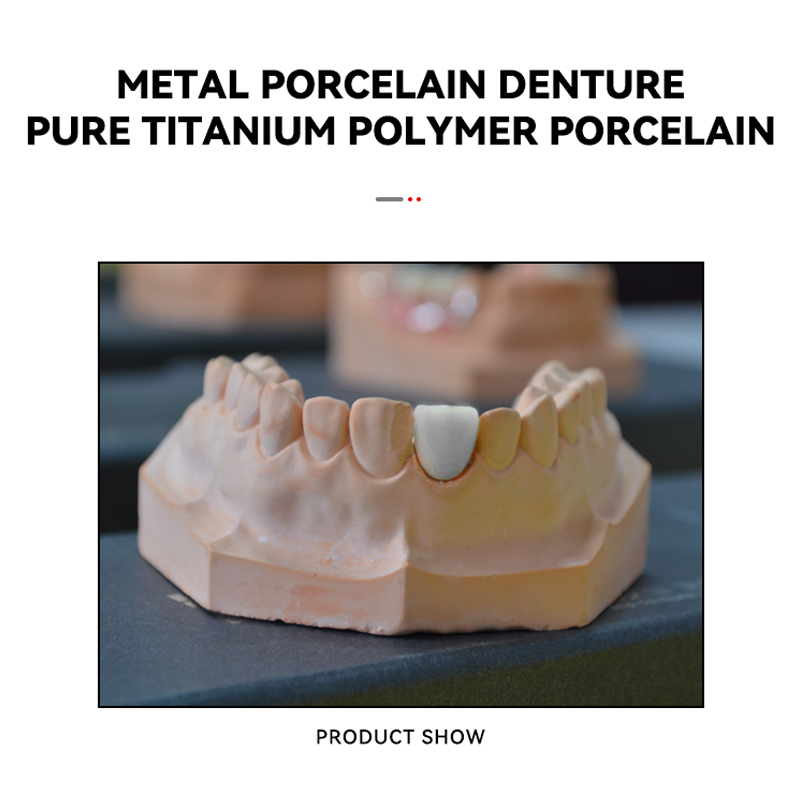

Pure titanium internal crown is metal, but non-magnetic, and does not affect medical examination like zirconia all-ceramic teeth. The external metal surface of the internal crown is made of polymeric porcelain covered by composite resin materials. The metal-ceramic combination is relatively loose, and can not bear a large bite force. The resin is easy to fall off during overpressure, so it is generally forbidden to chew hard food.

But it also has obvious advantages: Because the gold alloy bottom crown reflects the luster of natural teeth in the sun, and has good biocompatibility and is safe to use; high tightness; the combination of porcelain and metal is very good, and there are few cases of porcelain collapse.

Pure titanium porcelain teeth. Titanium metal is a kind of biological metal. Its biggest feature is that it has no toxic and side effects on human body and has the best biocompatibility.

All-ceramic teeth, as the name suggests, are pure porcelain porcelain technology without metal internal crowns. Because there is no metal restriction, the level and color of teeth can be reflected to the maximum extent, so the aesthetic effect of all-ceramic teeth is the best; and porcelain is safe and non-irritating to human body. However, due to the influence of porcelain strength, it is mainly used in the manufacture of porcelain veneer, porcelain inlay and porcelain single crown of anterior teeth.

Product function: The prosthesis restores the patient's chewing function and aesthetic function.

The remarkable performance characteristics of pure titanium polymer porcelain are:

Light specific gravity, high strength, small shrinkage, non-magnetic, wear-resistant and durable, and long service life. Specifically, low density. The density of titanium is 4.5g/cm3, which is about 1/4 of that of gold and 1/2 of that of cobalt-chromium alloy, which can reduce the burden on oral soft tissues; the thermal conductivity is low, only 1/17 of that of gold. Crowns, bridges or inlays can effectively protect the pulp and tooth tissue from external hot and cold acid stimulation, and will not cause gum atrophy and redness; the linear shrinkage rate is small, and the linear shrinkage rate of titanium is 1.75%, which is lower than that of gold alloy and cobalt chromium alloy has excellent applicability; x-rays are semi-resistive, x-ray films can pass through x-rays, and you can clearly see the tooth structure inside the titanium crown, so you can diagnose the health of the teeth without breaking the crown ; titanium metal is non-magnetic, and pure titanium series dentures will not be magnetized in a magnetic field. The passivation film on the surface of pure titanium metal has strong acid corrosion resistance and is not easy to be corroded. Mechanical properties, does not affect medical examinations such as nuclear magnetic resonance, x-ray films, and ct; has stable chemical properties and excellent biocompatibility, is non-toxic and harmless, has good biocompatibility with human tissue and blood, and is safe and harmless to the human body stimulation, so it is widely used in the medical field. The main disadvantages are: As the name suggests, pure titanium polymer is a polymer ceramic made by covering the outer surface of pure titanium inner crown with composite resin (or ceramic) material, and then cured by light. , the resin is easy to fall off or collapse under too much pressure, so generally try to avoid chewing hard food.

Company profile

Chongqing meitai medical equipment co., ltd. Is located in gangcheng industrial park, jiangbei district, chongqing. Formerly known as chongqing dingjie denture co., ltd., it was founded in 2004 and officially obtained national registration and approval in 2006. It is a professional enterprise engaged in dental prosthetics. The main production and processing of fixed denture, removable denture, appliance, implant teeth and other products. The company has 3 production lines, with more than 70 employees, 9 managers, and more than 20 after-sales team. The production workshop is more than 640 square meters, and the office building surface is more than 150 square meters. The company has been adhering to the "quality first, customer first, integrity-based, quality service" development philosophy, the pursuit of excellence, beyond the self, wholeheartedly to create denture quality, research and development and production of the majority of customers satisfied with a number of denture products, mainly used in oral patients functional repair and aesthetic repair. The company has obtained all kinds of relevant certificates and qualifications. After more than 10 years of hard work and hard work, the company has created a self-produced brand/oral denture products with high technical content, excellent quality and other remarkable characteristics, so that patients once again have a good experience of chewing function, the care spread to every corner, won the majority of oral patients and doctors trust, favor, recognition, praise and praise.

The company has advanced dental production process, technology, materials and production equipment, has a perfect quality management system, professional talent team, excellence, the pursuit of perfection, human, machinery, materials, the company unified deployment management and use, all materials choose ce european union standard and iso international standard and cfda national standard certification or registration. Products can be traced through the whole process to ensure the safety and effectiveness of products. The company has advanced production facilities and equipment: Yunjia, xianlin, pingtai, implant veneer and other high-precision scanners, hot die casting porcelain furnace, pure titanium casting, polymer porcelain light curing, laser/metal, resin 3d printing, five axis turning, polymer pressure, high frequency (filling) injection molding machine, high configuration artificial intelligence cad/cam computer aided design and other digital equipment.

Our self-developed and designed meiya self-owned brand production management system is committed to actively cultivating excellent management personnel and professional technical personnel, strict quality control, take the approach of going out to invite in, send staff to professional technical institutions to study, training, further study of professional production technology and management experience, and employ senior technical personnel in the industry to teach and guide the factory all year round. Introduce good management mode, create industry model, comprehensively improve the quality of denture product processing and professional technical level of practitioners, with "careful, dedication, focus on innovation, do a good job, do fine, do fine, stronger and bigger" craftsman spirit to build first-class brand, with excellent quality, technology, speed, service, win the market, seek development, we provide customers with satisfactory products and warm, thoughtful and convenient services, establish a good customer interaction network platform, to achieve better services for oral patients and doctors, and benefit the society.

The company has a high-quality staff, elite backbone, excellent after-sales service team, dedicated to your service...... , a comprehensive construction of digital solutions, truly realize the zero distance connection with customers. Our company also has a more solid pragmatic spirit, keep pace with the times, pioneering and innovative, with a more daily, thriving, spray bright tomorrow to share with you, become the best choice of your beautiful career, successful enabler and the most ideal partner, continue to create value for you.

Welcome friends from all walks of life to visit, guidance and business negotiations, hand in hand, jointly seize new opportunities, jointly create a better future!

Address: 6-5, building 4, no. 8, gangcheng east road, jiangbei district, chongqing (huaxiong intelligent times) Tel: 19122789485

Kang jinlie

3581959970@qq.com

07-21

07-21

07-21

07-21

07-21

07-19

07-18

07-18

07-18

07-18